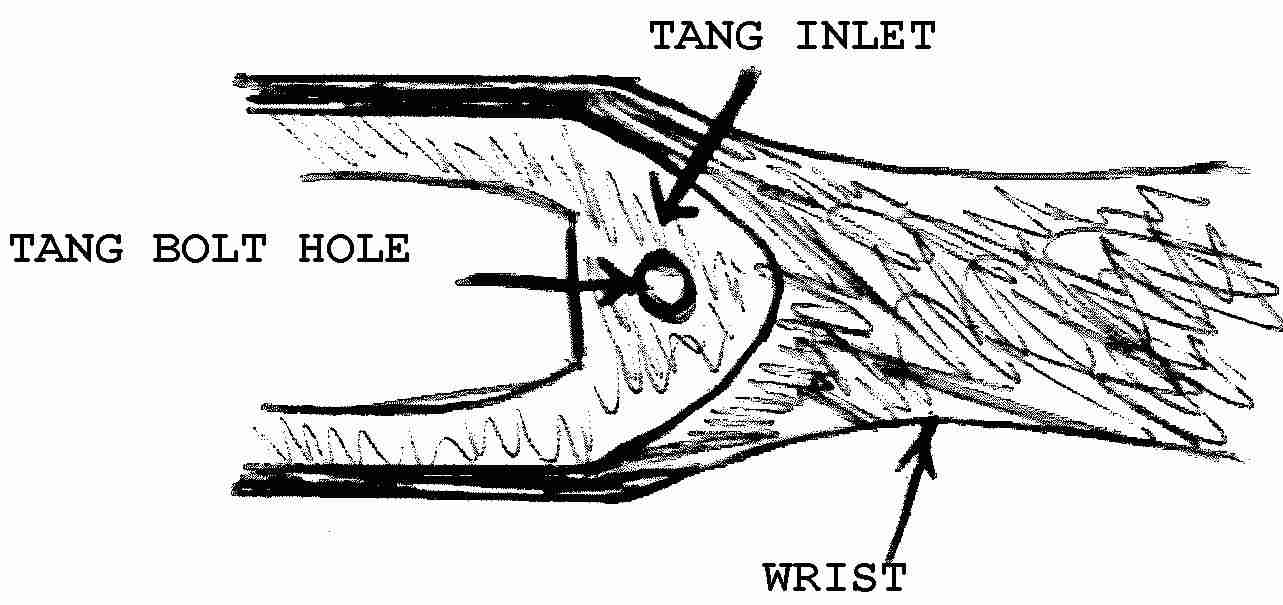

Partial Top View of Barrel and Action Inletting

Keep flat of stock top sharp where it drops into barrel and action inletting.

Text and graphics Copyright 2000-2006© Riflestock.Net. Written and compiled by Roger C. Linger. Email: austin_long@yahoo.com |